products

contact us

address: no.5, dongpei road, daitou industrial park, liyang city, jiangsu province

telephone: 0086-519-

fax: 0086-519-

mobile: +86-

mailbox: jszxby@liming.cc

product display

qby4 pneumatic diaphragm pump

main materials: cast iron, aluminum alloy, stainless steel, pp polypropylene, pvdf fluoroplastics, steel lined fluoroplastics

flow range: 0.5-78m3/h

head range: 0-84m

classification:

product description

product overview

qby4 series pneumatic diaphragm pump is a new type of conveying machinery, using compressed air as the power source, for a variety of corrosive liquids, liquids with particles, high viscosity, volatile, flammable, highly toxic liquids can be pumped to be sucked out. its performance parameters and the federal republic of germany's wlldenpumps, the united states of america mariowpumps similar.

mainly used

1、pumping peanut butter, pickles, mashed potatoes, small red sausage, jam apple syrup, chocolate and so on.

2、pump suction paint, gum, pigment.

3, adhesives and glue, all kinds of pumps available to suck.

4, all kinds of tile, porcelain, brickware and pottery glaze slurry.

5, oil wells drilled, with the pump to suck the sediments and grout.

6、pump all kinds of emulsions and fillers.

7、pumping all kinds of sewage.

8、pump for oil tankers, barge clearing warehouse sucking warehouse sewage.

9, hops and baking powder thin slurry, syrup, sugar density.

10、pump suction mine, pit, tunnel, ore dressing, slag in the water. pump suction cement grout and grey slurry.

11, all kinds of rubber slurry.

12, a variety of abrasives, corrosives, oil and mud, cleaning scale and general containers.

13, a variety of highly toxic, flammable, volatile liquids.

14, a variety of strong acid, alkali, corrosive liquids.

15、all kinds of high temperature liquid up to 150℃.

16、as a variety of solid-liquid separation equipment, the front stage of the pressure device.

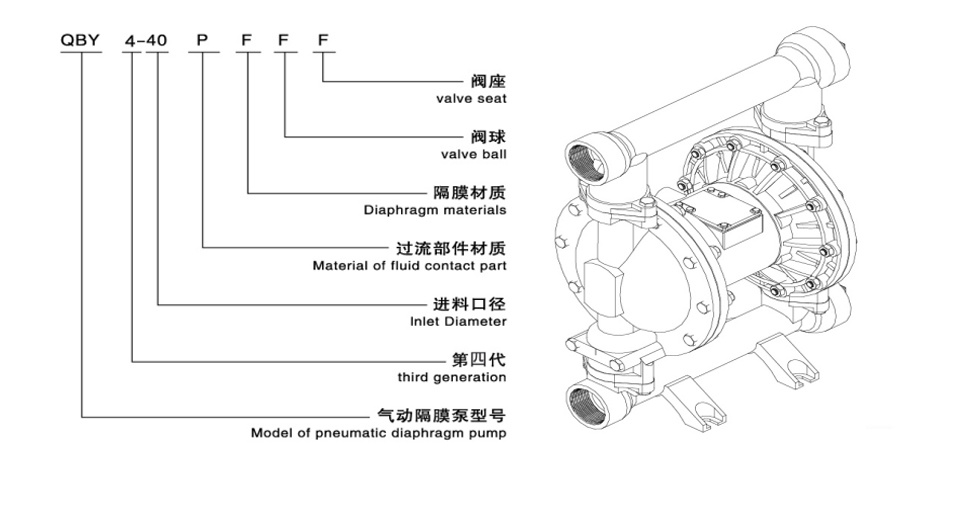

model description

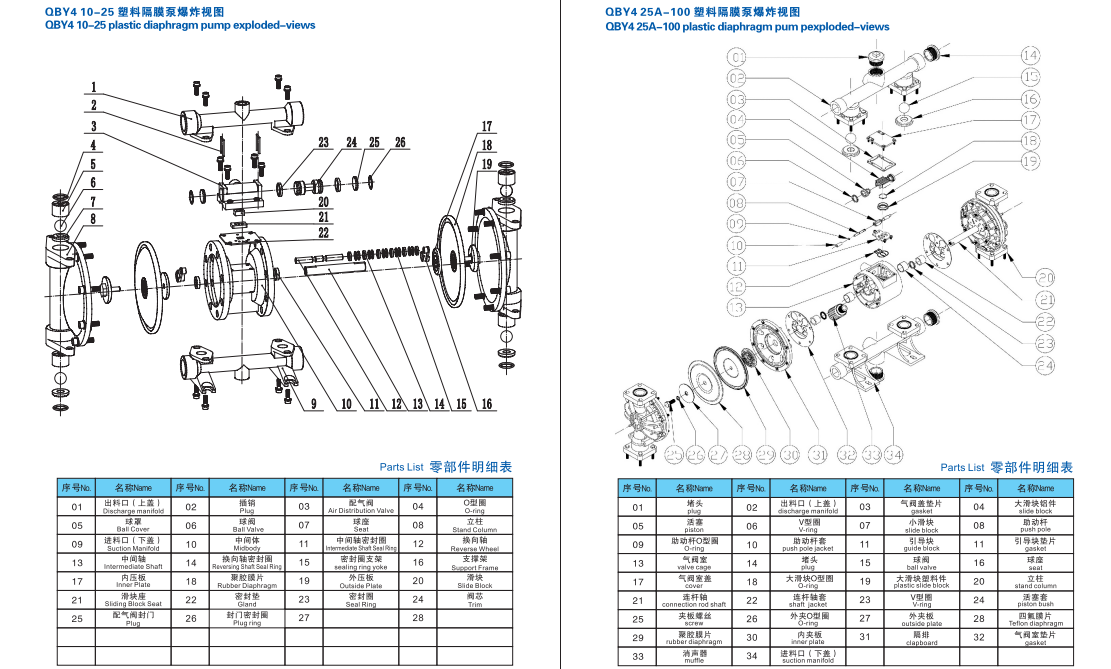

structure

model and parameter

| model | entry and exit calibres | maximum flow rate | maximum head | maximum suction range | maximum permissible particle size | maximum air pressure | maximum air consumption | |

|

(mm) |

(m³/h) |

(l/min) |

(m) |

(m) |

(mm) |

(kgf/c㎡) |

(m³/min) |

|

|

qby4-10 |

10 |

2.5 |

42 |

70 |

5 |

1 |

8.3 |

0.3 |

|

qby4-15 |

15 |

2.5 |

42 |

70 |

5 |

1 |

8.3 |

0.3 |

|

qby4-15a |

15 |

5 |

84 |

70 |

5 |

1 |

8.3 |

0.5 |

|

qby4-20 |

20 |

5 |

84 |

70 |

5 |

2 |

8.3 |

0.5 |

|

qby4-25 |

25 |

5 |

84 |

70 |

5 |

2 |

8.3 |

0.5 |

|

qby4-25a |

25 |

12 |

200 |

84 |

5 |

4.5 |

9 |

1.2 |

|

qby4-32 |

32 |

12 |

200 |

84 |

5 |

4.5 |

9 |

1.2 |

|

qby4-40 |

40 |

12 |

200 |

84 |

5 |

4.5 |

9 |

1.2 |

|

qby4-40a |

40 |

27 |

450 |

84 |

5 |

6 |

9 |

2.5 |

|

qby4-50 |

50 |

27 |

450 |

84 |

5 |

6 |

9 |

2.5 |

|

qby4-50a |

50 |

40 |

667 |

84 |

5 |

8 |

9 |

4.2 |

|

qby4-65 |

65 |

27 |

450 |

84 |

5 |

6 |

9 |

2.5 |

|

qby4-65a |

65 |

40 |

667 |

84 |

5 |

8 |

9 |

4.2 |

|

qby4-80 |

80 |

40 |

667 |

84 |

5 |

8 |

9 |

4.2 |

|

qby4-80a |

80 |

78 |

1300 |

84 |

5 |

11 |

9 |

7 |

|

qby4-100 |

100 |

40 |

667 |

84 |

5 |

8 |

9 |

4.2 |

|

qby4-100a |

100 |

78 |

1300 |

84 |

5 |

11 |

9 |

7 |

|

qby4-125 |

125 |

78 |

1300 |

84 |

5 |

11 |

9 |

7 |

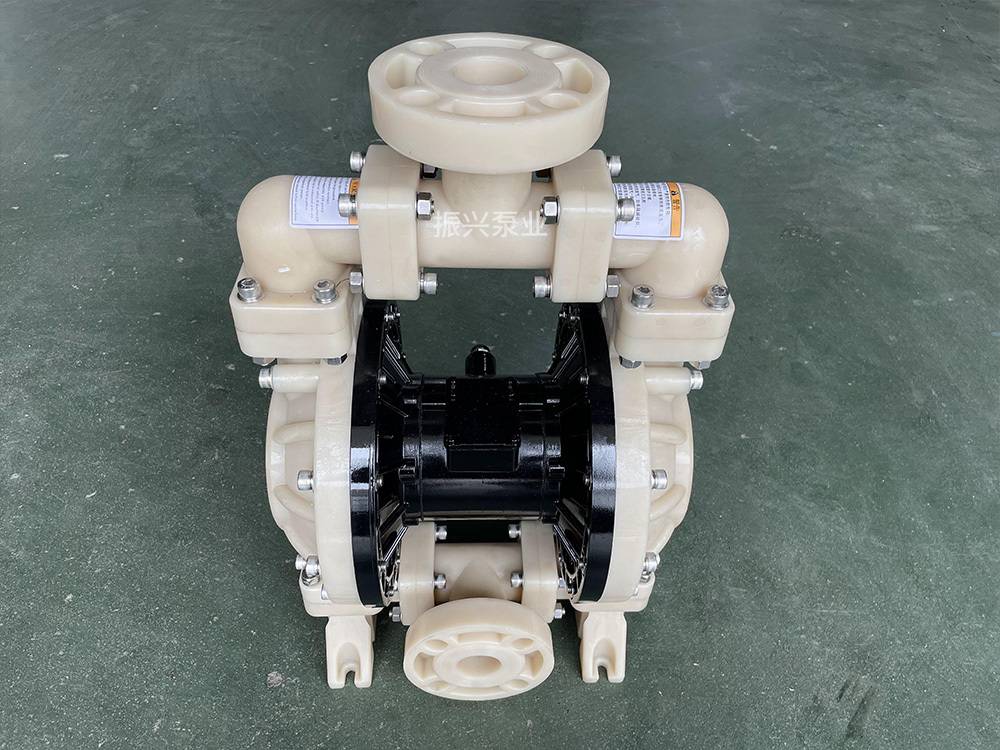

product real shot

product inquiry

contact information

address: no.5, dongpei road, daitou industrial park, liyang city, jiangsu province

telephone: 0086-519-

/

/ 87975898

fax: 0519-

service hotline: +86-

mailbox: jszxby@liming.cc

mobile website

wechat qr code